We aim to delight our customers with a highly flexible low volume manufacturing service. Creatingway Technology Limited was started by two experienced engineers with an extensive background in precision machining and mold tool manufacture. With an initial investment in two CNC machines, we quickly expanded our manufacturing capabilities to include CNC machining, injection molding, and a fully equipped sheet metal fabrication shop in our 3000m2 manufacturing facility. Located in Shenzhen, and with customers from all over the world, we have amassed extensive experience in developing hardware and components. We have a wide range of experience producing parts and complete products with varying levels of complexity from many different industries. This experience has enabled our team to develop in-depth knowledge when it comes to ensuring parts are made right the first time. Under our ISO9001 Quality Management System, we have developed robust and reliable procedures for managing projects. We have five inspectors that not only perform first-article, in-process, and final inspection, but they also work side by side with our shop floor staff to ensure that we meet our customers’ requirements. • 15 CNC Machines • 6 CNC Lathes • 2 CNC Press Brakes • 1 NC Sheer • 4 Electric Discharge Machines • 9 Injection Molding Machines • Optimal Projector • CMM • Hardness Tester

We work to the specifications provided in your design to create your custom-made product on time. Urgent projects are prioritized. Difficult to machine features are before sending to the manufacturing floor, saving you from costly reworks at a later stage.

Dedicated engineer who works with you directly. Your engineer will provide pre-manufacturing evaluation, revise the product, address difficult parts of the design and report on QA results.

Get a viability study and quote within 24 hours, and a product manufactured within a week.

Products are tested during and after production by our QA team. 100% inspection after production, with certificates and production test reports.

Test your prototype with small batch production. We can deliver anything between 10 and 10.000+ sets. Our after sales service helps you iterate and perfect your product in any batch size you might see fit.

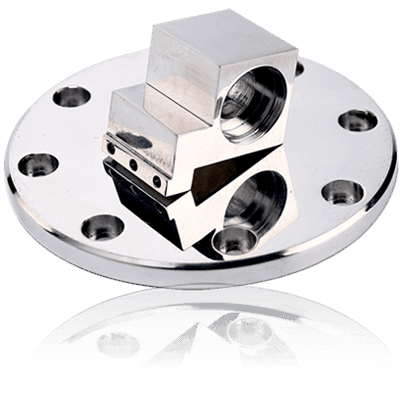

From a CAD model design, quickly manufacture prototypes using plastic materials such as Nylon, PC, PMMA, POM, PP, and UPE or metal materials including stainless steel, copper, bronze and aluminium.

Manufacture products ready for market with secondary finishing services such as anodizing coating, brushing, painting, sanding and color matching.

From our Chinese manufacturing base we produce world-class manufacturing products at a fraction of the cost of other markets.

Your products are delivered to your door on-time and on-budget. Want to see the proof? See our testimonials and case studies below from our global customer base.

Don’t see what you’re looking for?

Let us know, and we’ll work to create a custom solution.